KEY TO

LOW-CARBON

FUTURE

Get in touch

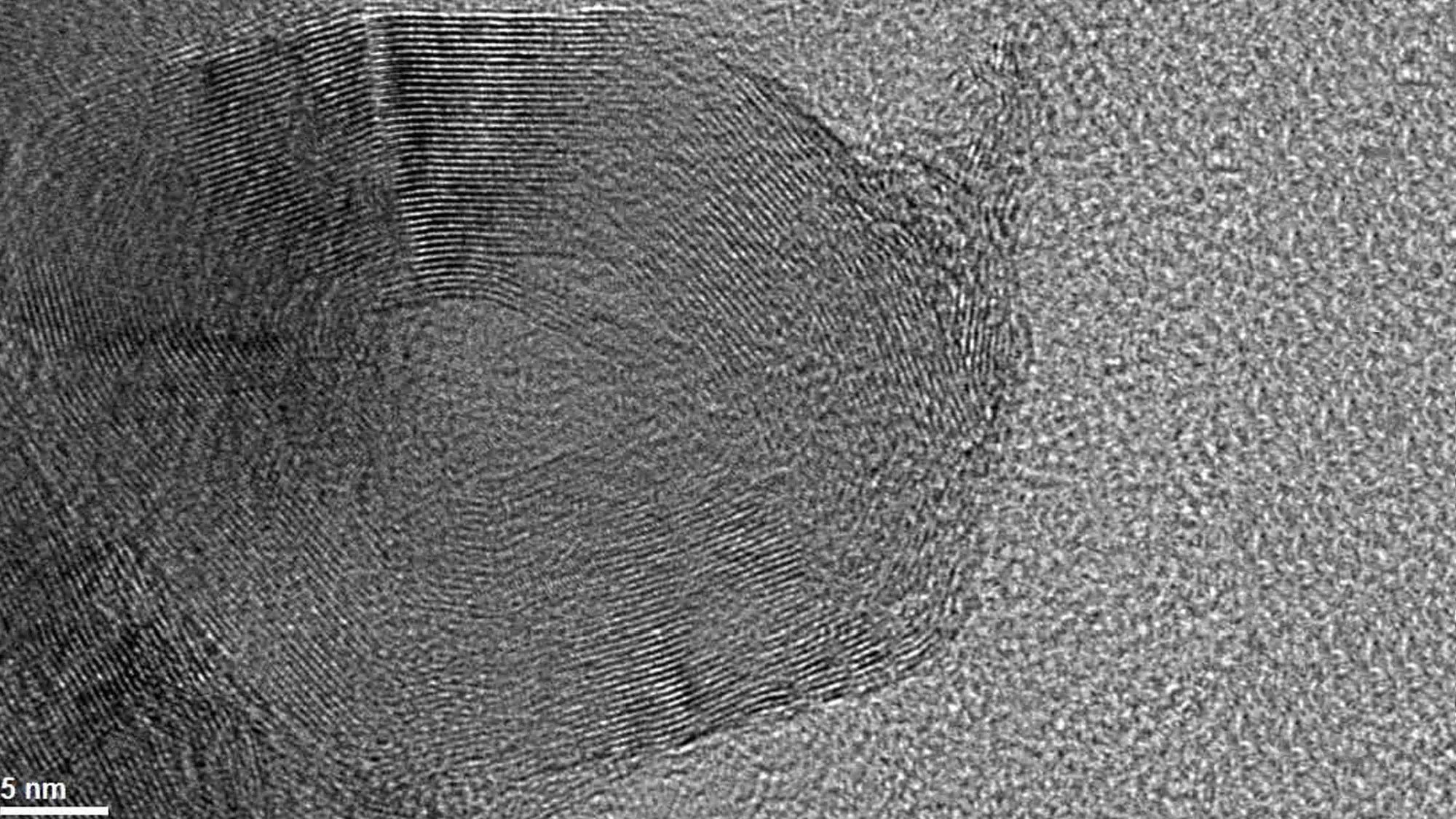

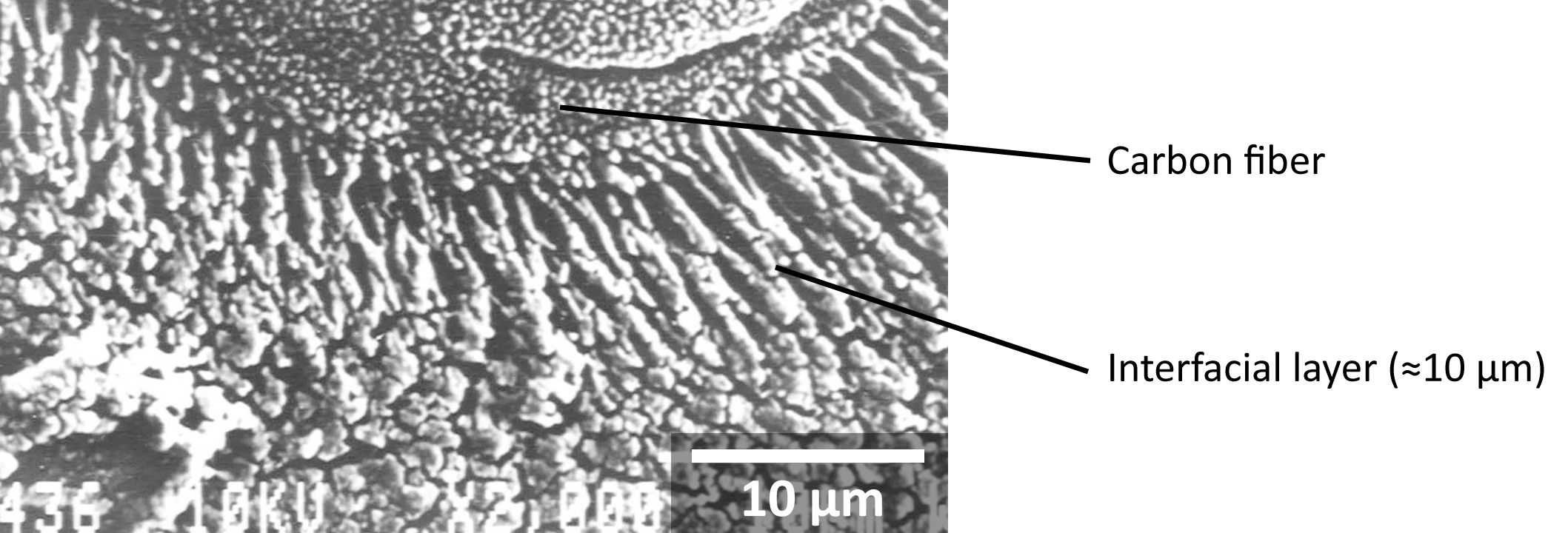

Cross section of carbon fiber composite sample nano-structured by our product for Ultra Lightweighting.

TOROIDAL

GRAPHENE

Toroidal graphene represents a groundbreaking carbon nanostructure with a closed-loop topology of sp²-hybridized carbon atoms. Its unique toroidal geometry fosters a closed π-electron system, enabling extraordinary field amplification effects driven by quantum and curvature-induced phenomena. Unlike planar or cylindrical nanostructures, toroidal graphene exhibits unparalleled electromagnetic field localization, positioning toroidal graphene as a cornerstone for sustainable and high-performance technologies.

INDUSTRIAL

CASE STUDIES

The performance enhancement capability of Toroidal graphene has been documented by us in several industrial case studies, where components made of composite materials nano-structured by Toroidal graphene at concentrations of 0.0025-0.01wt% was demonstrated under real operational conditions (TRL-level 7):

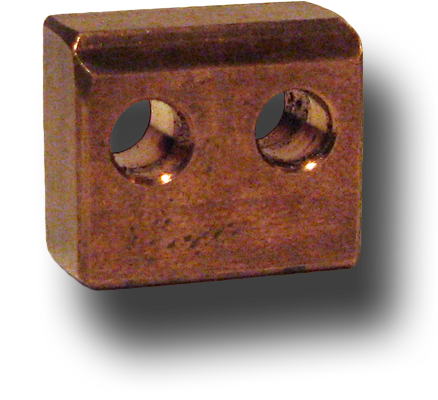

• The collaboration between Solerial Matusions, Scania, and the Swedish Metals Research Institute (Swerim) in 2022 in a pre-study to develop a lead-free bronze alloy for truck gearbox pads resulted in the creation of a lead-free Toroidal graphene-Bronze alloy with significantly higher wear resistance than traditional leaded bronze. The tribological evaluation showed a 324% increase in wear resistance compared to leaded bronze as well as the capability to dissipate frictional heat more efficiently, leading to lower operating temperatures and reduced thermal-induced wear.

• A grinding support made of nano-structured bronze (tin copper) was tested by Thyssen in Germany. The test showed an improvement in abrasive wear resistance of 500% compared to Thyssen’s grinding supports.

•A tool holder for turning was made of nano-structured carbon fiber composite. In demonstrations it allowed turning at 200,000 rpm with a maximum tool deflection of 2 mm, which is an improvement by a factor of 20 compared to steel. SP Technical Research Institute of Sweden conducted independent testing of the compression modulus of the tool holder, which verified a performance enhancement of over 40% compared to Japanese world-leading carbon fiber manufacturer Toray.

• A pervaporation membrane for separating azeotropic mixtures made of nano-structured thermoplastic (PPO) didn’t influence the pervaporation properties but showed an improvement in biaxial tensile strength of 85%.

• Chemical resistance to nuclear waste in borosilicate glass, nano-structured with our product, has been measured to 400% improvement.

• Laboratory environment feasibility studies have shown improvements in tensile strength of epoxy by 39%; in flexural modulus of T700 carbon fiber fabric by 45%, which is equivalent to T1300-level; and in flexural modulus of engineering plastics by 54%.

TECHNOLOGY

Toroidal graphene molecule

The toroidal graphene molecule is a nano-scientifically engineered zero-dimensional1 sp2-hybridized carbon allotrope, consisting of 20-40 defect-free graphene layers without function-group content, geometrically fixed in a closed conjugated system with delocalized pi-electrons interacting freely in circular motion in the closed loop of the cyclic structure of the toroid instead of being occupied in pi-bonds with adjacent graphene layers. Thus, the toroidal graphene molecule exhibits delocalization of pi-electrons from the multiple layers in coherent oscillations across the entire molecule.

1. 0D nanomaterials have zero dimensions larger than the nanoscale and thus have all three dimensions confined at the nanoscale, as opposed to 2D nanomaterials like 2D graphene, which have two dimensions larger than the nanoscale, and one dimension confined at the nanoscale. Nanoscale refers to dimensions on the order of nanometers, ranging from 1 to 100 nanometers.

Giant resonance

The coherent motion of delocalized pi-electrons arises from quantum mechanical principles, where neighboring pi-electrons exhibit wave-like constructive interference patterns, which occur when the wavefunctions of pi-electrons of the multiple layers align in phase, leading to an amplification of the oscillations that ultimately trigger a resonant response.

This resonance phenomenon, known as giant resonance, leads to a significant enhancement of the electromagnetic field of the molecule, amplifying its intensity by a factor of 30,000, as observed in Raman scattering experiments, where the amplification results in stronger Raman signals, providing direct evidence of the giant resonance phenomenon.

NANO-

STRUCTURING

CAPABILIITY

Extreme electron mobility together with exceptional structural and thermal integrity makes Toroidal graphene the ideal nanostructuring agent for enhancing composite materials such as metal alloys, engineering plastics, and carbon fiber.

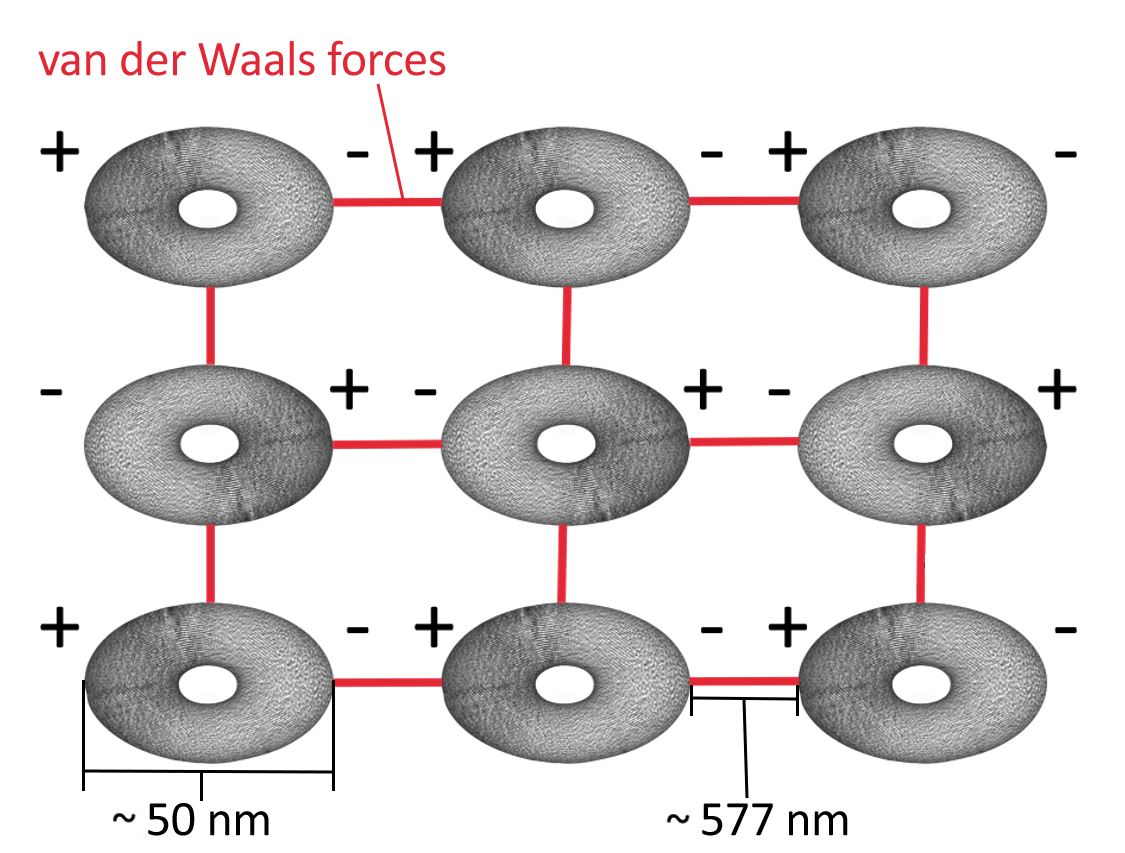

The incorporation of toroidal graphene molecules into a composite material significantly influences its overall performance. When uniformly dispersed, they establish a stable internal network within the material. The network stability comes from the alignment and attraction of temporary dipoles between the toroidal graphene molecules, a phenomenon known as van der Waals forces.

The van der Waals forces exerted by the toroidal graphene molecules demonstrate heightened strength and expanded range, owing to modified electron density and electronic polarization induced by giant resonance.

The interlayer shear properties of the toroidal graphene molecule are characterized by exceptionally high shear strength, preventing the individual graphene layers from being separated, even during extreme processing conditions. This phenomenon arises from the strong covalent bonding within each defect-free graphene layer and the quantum mechanical interlayer interactions, which collectively resist shear deformation and ensure structural integrity.

Densified interfacial layers

Dispersing toroidal graphene molecules uniformly in a broze matrix with a molecular spacing of 126 nm, and thereby ensuring optimal interaction between the temporary dipoles of adjacent toroidal graphene molecules, promotes the formation of denser, more compact interfacial layers between the toroidal graphene molecules and the surrounding copper atoms.

Amplified van der Waals forces between the toroidal graphene molecules and the copper atoms play a crucial role in promoting stronger interactions at the interfaces. The attractive forces pull the copper atoms closer to the toroidal graphene molecules, thereby contributing to the densification of the interfacial layers with improved cohesion and adhesion.

Superior electrical and thermal conductivity

The densified interfacial layers within the nanostructured copper facilitate better contact between the toroidal graphene molecules and the copper atoms, improving transfer pathways and mobility of charge carriers and phonons through the composite material, as well as reducing scattering, and minimizing energy losses, ultimately reducing resistance and thus contributing to higher electrical and thermal conductivity.

Stronger intermolecular interactions also lead to a smoother surface and reduced frictional resistance, resulting in improved durability and longevity of the material.

In the case of carbon fiber composites, an interfacial layer is formed around the carbon fibers as well.

COMPETITION

The nanomaterial industry has been largely shaped by carbon nanotubes (CNTs) and 2D graphene, the two most hyped nanomaterials in history.

Before the Nobel Prize for graphene in 2010, CNTs were the dominant go-to choice for funding approvals, with evaluators prioritizing them in government grants and research investments. Since then, 2D graphene has taken over as the preferred material, often securing funding based on its reputation rather than demonstrated large-scale feasibility. While CNTs are no longer prioritized, the combined era of dominance for these two nanomaterials has shaped the direction of research and commercialization efforts for over 30 years, driving funding decisions and technological focus within the nanotechnology sector.

Carbon nanotubes (CNTs)

Early Theoretical Foundations (1950s-1970s)

The concept of cylindrical carbon structures was first theorized in the mid-20th century, with early studies on rolled-up graphene sheets dating back to the 1950s and 1960s. In 1976, Morinobu Endo synthesized hollow carbon filaments that closely resembled modern CNTs, though at the time they were referred to as carbon fibers.

Discovery and Recognition (1991)

In 1991, Sumio Iijima of NEC officially discovered multi-walled carbon nanotubes (MWCNTs) while analyzing carbon structures produced via arc discharge—a technique already used for fullerene synthesis. This discovery marked the beginning of CNT research as a distinct field. In 1993, both Iijima and Donald Bethune independently discovered single-walled carbon nanotubes (SWCNTs), which exhibited even more remarkable properties.

The CNT Boom (19902-2000s)

Throughout the late 1990s and early 2000s, CNTs were hailed as a “wonder material,” promising revolutionary applications in electronics, materials science, and nanomedicine due to their exceptional mechanical strength, electrical conductivity, and thermal properties. Industry and academia focused heavily on synthesis techniques, including chemical vapor deposition (CVD), laser ablation, and arc discharge.

Hype and Commercial Challenges (2000s-2010s)

Despite their extraordinary properties, CNTs faced major hurdles in scalability, cost, and material purity. Issues such as dispersion, batch-to-batch variability, and difficulty in integrating CNTs into composites slowed their commercial adoption. While CNTs found niche applications in composite materials, energy storage, and coatings, they never achieved the widespread industrial impact once anticipated.

Decline in Focus and Shift to Graphene (Post-2010s)

With the 2010 Nobel Prize in Physics awarded for graphene, attention—and funding—shifted toward 2D materials, particularly graphene. As a result, CNTs lost their status as the dominant nanomaterial for government grants and research funding. Although they remain relevant in specialized applications, such as electronic components, conductive composites, and biomedical uses, their mainstream appeal has diminished, marking a transition in nanotechnology’s priorities.

CNTs have been used as an additive in tens of thousands of attempts to modify materials, yet comprehensive commercialization remains elusive. A notable exit from the CNT market was Bayer AG, which once had significant investments in CNT production but ultimately withdrew, stating that the potential applications for CNTs were “fragmented, with comprehensive commercialization not likely in the foreseeable future.” This sentiment reflects the broader trend of diminishing industrial interest in CNTs as graphene and other nanomaterials have taken center stage.

2D Graphene

Discovery and Isolation of 2D graphene

- 2D Graphene, a single layer of carbon atoms arranged in a honeycomb lattice, was first isolated in 2004 by Andre Geim and Konstantin Novoselov using the Scotch tape method, a simple exfoliation technique that separates thin layers of graphite into monolayers.

- This groundbreaking discovery earned them the 2010 Nobel Prize in Physics for proving 2D Graphene’s existence and demonstrating its unique properties.

- Early enthusiasm surrounding 2D Graphene led to widespread misconceptions, particularly the belief that 2D Graphene sheets could directly replace existing materials in real-world components. However, practical challenges, such as the small size of 2D Graphene flakes and their inherent defects, limit 2D Graphene’s usability as standalone materials.

2D Graphene as Flakes

- In practical terms, 2D Graphene is usually available as 2D Graphene flakes—tiny fragments of monolayer or few-layer 2D Graphene, typically micrometers in size.

- These flakes are prone to various defects, which impact their performance:

- Structural defects: Vacancies and dislocations in the atomic lattice that weaken mechanical properties.

- Edge defects: Dangling carbon bonds at the edges of flakes, which are highly reactive.

- Chemical defects: Functional groups, contaminants, or adsorbed molecules from processing.

- Wrinkles and ripples: Out-of-plane distortions that affect 2D Graphene’s flat 2D nature.

- These defects reduce 2D Graphene’s strength, electrical conductivity, and thermal conductivity, causing its real-world performance to fall short of theoretical predictions.

Challenges of Using 2D Graphene Flakes

- The main focus of 2D Graphene projects involves developing methods to integrate 2D Graphene into composite materials (e.g., polymers, ceramics, or metals) to enhance properties such as strength, conductivity, and heat resistance. However, incorporating 2D Graphene flakes into host matrices poses significant challenges:

- Agglomeration: 2D Graphene flakes naturally clump together due to van der Waals forces and the reactivity of dangling bonds, reducing their surface area and usability.

- Dispersion Issues: Achieving uniform dispersion of 2D Graphene flakes in a composite is difficult but critical for consistent performance.

- Interfacial Bonding: 2D Graphene often interacts weakly with host materials, limiting the transfer of properties like mechanical reinforcement or electrical conductivity.

2D Graphene vs. Graphite: Defining the Transition

- A monolayer of 2D Graphene exhibits unique properties, such as high electrical conductivity, mechanical strength, and transparency, that are fundamentally different from graphite, the bulk material composed of stacked graphene layers.

- However, even a two-layer 2D Graphene flake begins to exhibit interlayer interactions, such as:

- Van der Waals forces, which cause layers to stick together and mimic the behavior of graphite.

- Electronic coupling, which disrupts the unique linear band structure of monolayer 2D Graphene, shifting it toward graphite-like parabolic or hybridized bands.

- Few-layer graphene (FLG): Materials with up to 10 layers are often classified as 2D Graphene for practical purposes, but their properties are closer to graphite as more layers are added.

- Scientifically, only monolayer 2D Graphene is true 2D Graphene, while bilayer and few-layer structures represent a transitional state toward graphite.

Functionalization of 2D Graphene

- To improve 2D Graphene’s usability, flakes are often functionalized by attaching chemical groups (e.g., hydroxyl, carboxyl, or alkyl groups). Functionalization helps prevent agglomeration and improves dispersion in host materials, but it degrades 2D Graphene’s intrinsic properties:

- Disruption of the sp² Lattice: Covalent functionalization converts sp²-hybridized carbons into sp³-hybridized ones, breaking the π-electron network that gives 2D Graphene its high electrical and thermal conductivity.

- Introduction of Defects: Functionalization processes, such as oxidation, create lattice imperfections that weaken mechanical strength and reduce carrier mobility.

- Increased Surface Roughness: Chemical groups attached to the surface alter 2D Graphene’s smoothness and reduce optical transparency.

- Despite these trade-offs, functionalization is essential for integrating 2D Graphene into composites, coatings, or biomedical applications.

High Cost and Fragility of Monolayer 2D Graphene

- Monolayer 2D Graphene, such as the 1 square inch sheets sold by Sigma-Aldrich for $334, is prohibitively expensive at an equivalent price of $661 billion per kilogram, reflecting the challenges of producing and handling it.

- Even if isolated from its copper substrate, freestanding monolayer 2D Graphene is extremely fragile and prone to:

- Tearing: Due to its atomic thinness and lack of support.

- Wrinkling or folding: Induced by mechanical stress or minor disturbances like a small gust of air.

- Loss of Properties: Without a substrate, 2D Graphene’s mechanical, electrical, and thermal properties degrade quickly.

Funding Definitions of 2D Graphene

- Organizations like SIO Grafen, Sweden’s innovation agency for graphene, set practical definitions to classify materials with 10 or fewer layers as graphene to facilitate funding and industrial applications. They also include functionalized graphene derivatives such as graphene oxide, which have significantly lower carbon content, acknowledging their potential in real-world applications despite diverging from pristine graphene’s properties. While this approach broadens the scope of materials eligible for support, real-world commercialization of graphene-enhanced products remains challenging, as evidenced by pilot-stage projects evaluated during the agency’s activities.

- The 9-year evaluation of SIO Grafen highlights two notable startups as being the closest to commercialization, illustrating the challenges of scaling graphene-based innovations. One company demonstrated significant performance improvements under controlled laboratory conditions but was unable to replicate these results in large-scale production trials, likely due to difficulties in scaling and adapting the material to real-world manufacturing environments. Another startup developed a graphene-based solution that showed promising functional enhancements, including improved material properties and performance characteristics. However, the technology remains at the pilot stage, with ongoing efforts focused on refining dispersion techniques and optimizing production scalability.

Interlayer Interactions and Agglomeration

- Monolayer 2D Graphene has dangling bonds at its edges and π-electrons in its basal plane, which create strong tendencies for flakes to agglomerate:

- Van der Waals forces: Pull flakes together into stacked structures.

- π–π stacking: Interactions between the electron clouds of adjacent layers encourage restacking.

- Agglomeration diminishes 2D Graphene’s intrinsic properties, such as its large surface area and conductivity, making it behave more like graphite.

AEROSPACE

ULTRA

LIGHT-

WEIGHTING

With a systems-level approach, which involves considering the potential for ultra lightweighting from the beginning of the design process, it is possible to optimize the design of a 300-seat, 140-ton carbon fiber jet with a list price of $325m.

One kilogram of our product ultra-lightweights the carbon fiber parts of a 140-ton carbon fiber jet and addresses the following five primary areas of aerospace lightweighting:

• Weight savings – Our product allows for weight savings of 40% of the carbon fiber composite parts or a total of 28 tons, which equals cost savings of $8.7m.

• Fuel consumption – Our product allows for a reduction in fuel consumption by 20% or 10+ tons of fuel for a single Atlantic crossing, which equals cost savings of $10m over the life of the aircraft.

• CO2 emissions – Our product allows for a reduction in CO2 emissions by 20% or 30+ tons for a single Atlantic crossing.

• Range – Our product improves range flexibility by 20% or 2,800 km, thereby increasing the number of possible non-stop destinations around the world.

• Aircraft lightning protection – Carbon fiber composites cannot mitigate the potentially damaging electromagnetic effects from a lightning strike. The most frequently selected solution to this problem is to introduce metals back into the aircraft. The metal mesh and expanded foil added to the composite structure layup for this purpose are negating any lightweighting measures and don’t contribute to structural strength. Carbon fiber composites enhanced with our product serves as an electrical shield around the structure that protects against lightning strikes and at the same time contributes to structural strength.

OPPORTUNITY:

WORLD

LEADING

CARBON

FIBER

COMPOSITE

Any carbon fiber manufacturer with T800-level carbon fiber could with the help of our product surpass the current world leader in carbon fiber composites, Toray of Japan, by more than 30% or nearly 1,000 MPa, which will be the biggest leap in the evolution of carbon fiber composites in over 30 years.

SUSTAINABILITY

Our product’s capability to enhance the electrical conductivity of copper aligns with multiple United Nations' Sustainable Development Goals (SDGs) for 2030, particularly in the areas of industry, innovation, and infrastructure; clean energy; and responsible consumption and production.

- Affordable and Clean Energy (SDG 7):

- Improved electrical conductivity can enhance the efficiency of electrical systems, reducing energy loss during transmission and distribution.

- Higher conductivity allows for more efficient energy generation, contributing to the goal of affordable and clean energy.

- Industry, Innovation, and Infrastructure (SDG 9):

- Enhanced electrical conductivity can lead to the development of more efficient and innovative electrical infrastructure and technologies.

- Improved conductivity can contribute to the advancement of electric vehicles, renewable energy systems, and smart grids, supporting sustainable industrialization and infrastructure development.

- Responsible Consumption and Production (SDG 12):

- By increasing the efficiency of electrical systems, the product can contribute to reduced resource consumption and waste associated with energy production and transmission.

- The enhanced conductivity may lead to longer-lasting and more reliable electrical components, promoting sustainable consumption patterns.

- Climate Action (SDG 13):

- Increased electrical conductivity can contribute to the development and adoption of cleaner energy technologies, thereby mitigating the impact of climate change.

- Efficient energy transmission and reduced energy loss can result in lower greenhouse gas emissions associated with energy production and consumption.

- Partnerships for the Goals (SDG 17):

- Collaborations between the manufacturers of the product, the copper industry, and other stakeholders can foster partnerships aimed at achieving sustainable development goals.

- Sharing knowledge and technologies related to enhanced electrical conductivity can contribute to a collective effort to address global challenges.

LET'S GET

TOGETHER.

If you believe that we may have a technology that could be of benefit to your company ...

or if you just want to chat …

Project partners